ACE3600 GATE2MDLC (G2M) FEP

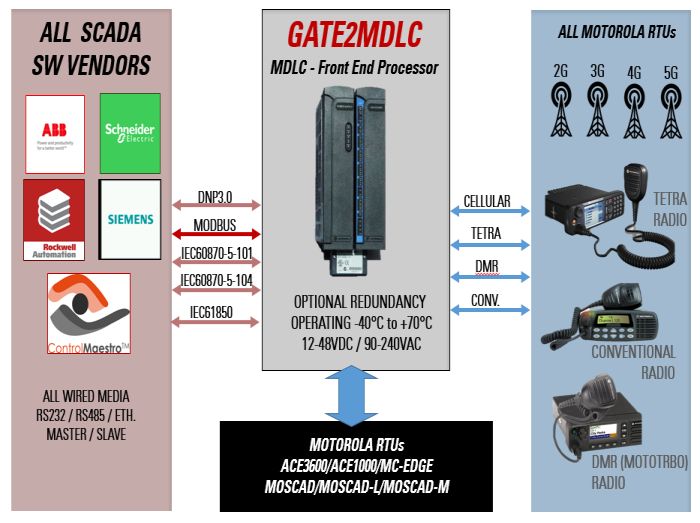

GATE2MDLC provides seamless connectivity between Motorola RTU based system to SCADA SW through open and standard protocols of MODBUS (or IP), DNP3.0 (or IP), IEC60870-5-101, IEC60870-5-104 but not limited to.

With the capacity to handle more than 200,000 I/O points (SCADA tags) per CPU, GATE2MDLC supports all Motorola RTU models; MOSCAD/L/M, ACE3600, ACE1000 and MC-EDGE. It simplifies and streamlines the application programming process for Motorola RTUs eliminating the need to develop any application at FEP.

GATE2MDLC serves as central component for facilitating MDLC communication between Motorola RTUs and the SCADA center. Additionally, it directly replaces outdated and non-functional solutions such as Motorola MCP-M, MCP-T, M-OPC, and IP GATEWAY, providing an efficient and modern up-to-date embedded alternative.